A COMPREHENSIVE APPROACH

CAPABILITIES A-Z

Discover our range of innovative solutions and services.

ACQUISITION

We have extensive corporate knowledge of Aerospace platform acquisition and full life cycle sustainment requirements and processes. We have field offices and support work at all three major USAF Air Logistics Complexes (Hill AFB, Robins AFB, and Tinker AFB).

In particular, we have directly supported the A-10 Thunderbolt II’s Precision Engagement (PE) upgrade program, Operational Flight Program (OFP) development and its software releases, flight test support, Electronic Warfare (EW) hardware upgrades, Configuration Management, Engineering Services, and Advisory and Assistance Services (A&AS) support across multiple acquisition disciplines and numerous programs since 2005.

ACQUISITION

We have extensive corporate knowledge of Aerospace platform acquisition and full life cycle sustainment requirements and processes. We have field offices near, and have supported work at, all three major USAF Air Logistics Complexes (Hill AFB, Robins AFB, and Tinker AFB).

In particular, we have directly supported the A-10 Thunderbolt II’s Precision Engagement (PE) upgrade program, Operational Flight Program (OFP) development and its software releases, flight test support, Electronic Warfare (EW) hardware upgrades, Configuration Management, Engineering Services, and Advisory and Assistance Services (A&AS) support across multiple acquisition disciplines and numerous programs since 2005.

AEROSPACE

LOREM IPSUM DOLOR SIT AMET

In hac habitasse platea dictumst. Vivamus viverra pretium purus, vehicula fermentum ipsum posuere a. Nulla commodo dapibus odio sit amet placerat.

Nulla sed sollicitudin arcu. Integer lacus nulla, ornare eu varius a, dapibus sed lacus. Etiam facilisis risus vitae lacus mattis placerat. Duis cursus, mi vitae pharetra interdum, lacus massa varius neque, euismod convallis eros sem vel dolor. Sed nibh libero, tempor sit amet tempor non, vulputate vel enim.

LOREM IPSUM DOLOR SIT AMET

In hac habitasse platea dictumst. Vivamus viverra pretium purus, vehicula fermentum ipsum posuere a. Nulla commodo dapibus odio sit amet placerat.

Nulla sed sollicitudin arcu. Integer lacus nulla, ornare eu varius a, dapibus sed lacus. Etiam facilisis risus vitae lacus mattis placerat. Duis cursus, mi vitae pharetra interdum, lacus massa varius neque, euismod convallis eros sem vel dolor. Sed nibh libero, tempor sit amet tempor non, vulputate vel enim.

ARMOR SYSTEMS

LIGHTER, STRONGER, BETTER

KIHOMAC's innovative use of composite materials allows for an overall lighter plate while providing military grade protection.

To learn more about our production capabilities contact us at info@kihomac.com

FACILITIES AND CAPABILITIES

KIHOMAC's Center for Advanced Manufacturing, located in Layton, Utah, boasts an expansive 100,000 square foot work floor.

Arrayed with state-of-the-art equipment, we are able to produce top-of-the-line body armor products for both law enforcement and military use.

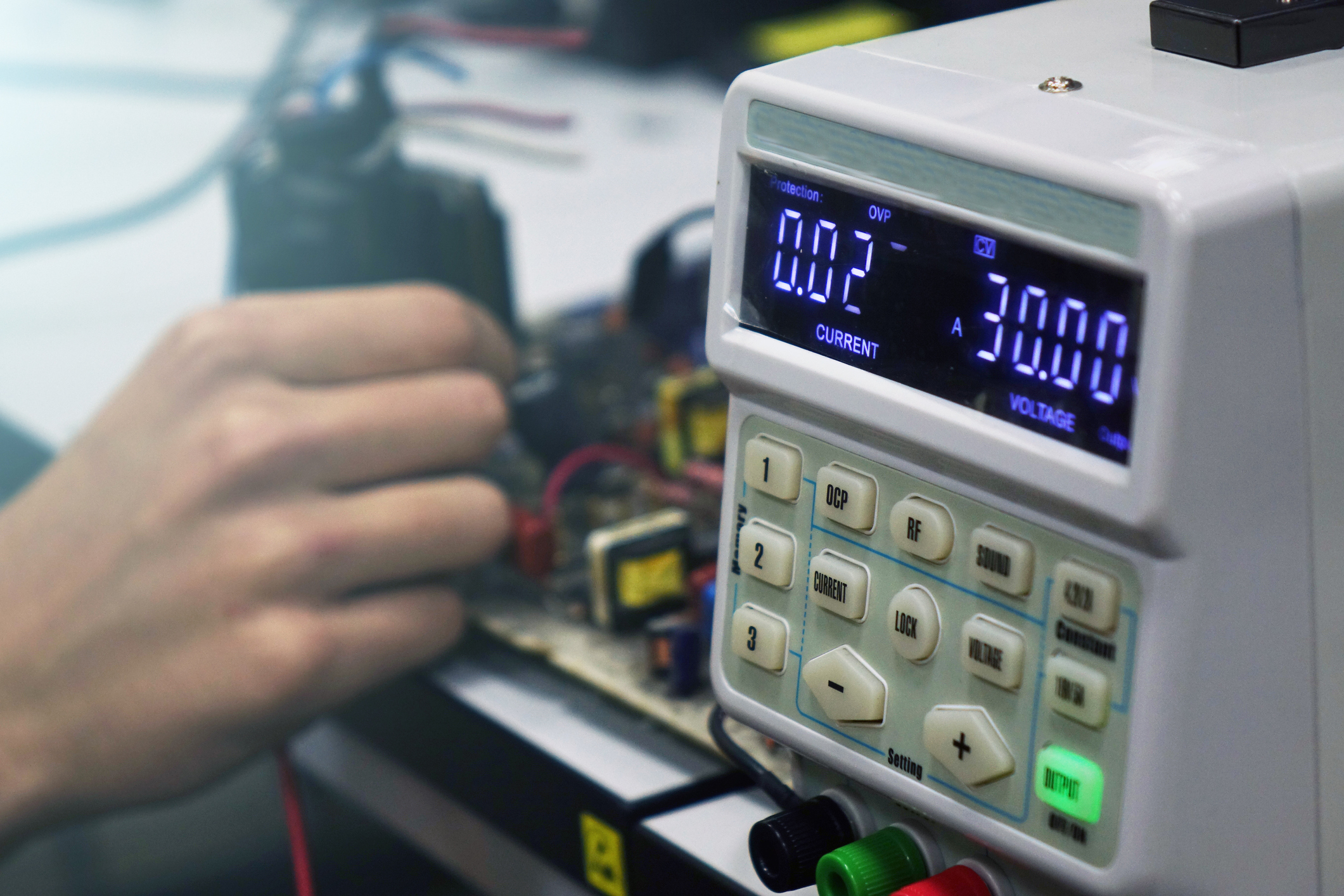

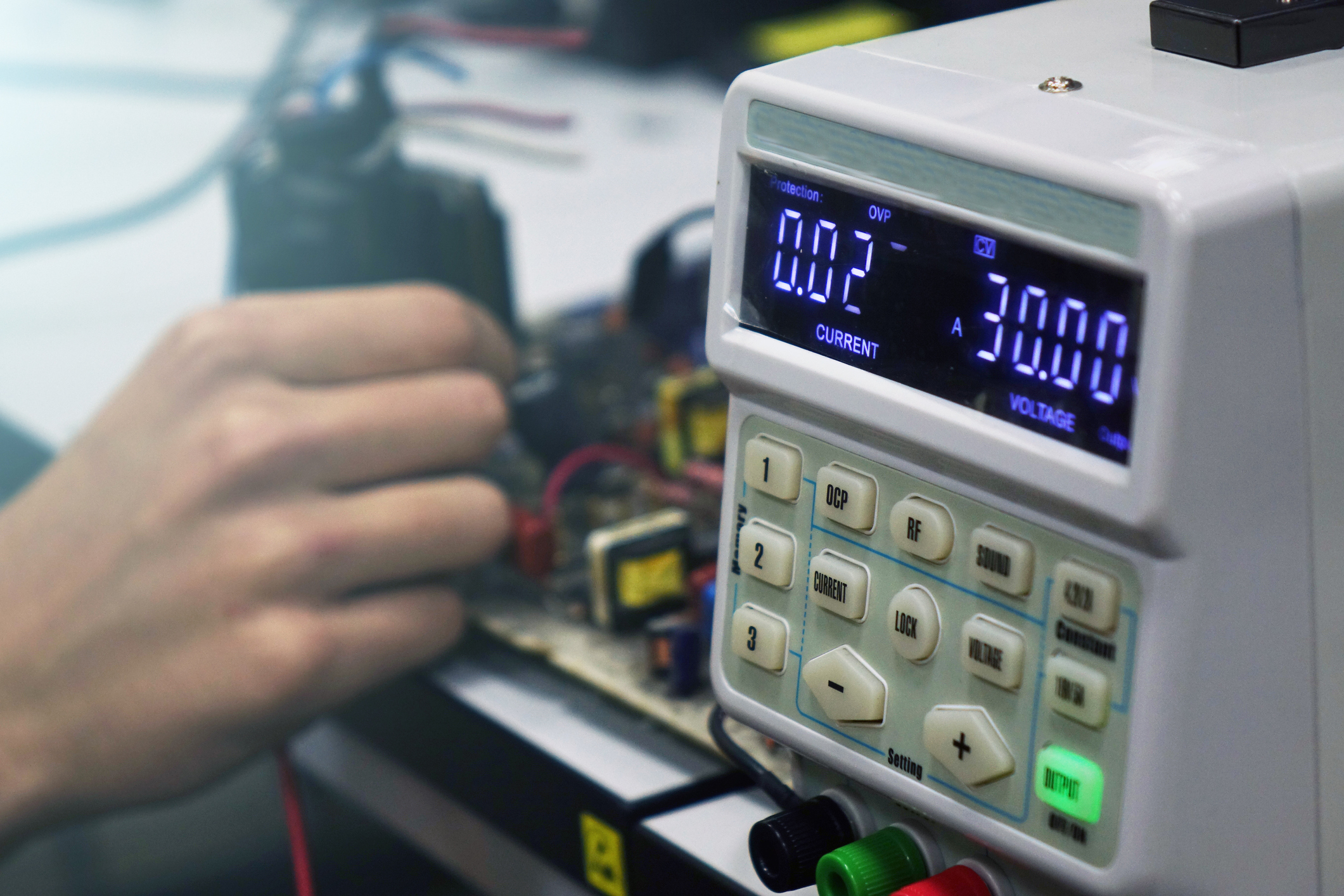

CALIBRATION SOLUTIONS

KIHOMAC offers a full spectrum of calibration capabilities

The proper application of measurement science reduces cost while improving performance, reliability and product quality. Our expertise includes the following: metrology engineering, precision measuring system development, measurement uncertainty analysis, calibration logistics analysis and support, laboratory operations analysis, predictive analysis, measuring equipment obsolescence management, workload planning and analysis, laboratory equipment allowancing, performance based budget modeling, program and project management support, professional staff support, requirements and technical management, agile software development, and technical publication development.

KIHOMAC supports the Naval Air Systems Command (NAVAIR) Metrology and Calibration (METCAL) Program at Patuxent River, MD, coordinating calibration support with weapon system acquisition managers to include calibration standards (CALSTDs) initial outfitting, development of calibration support plans, and procedures for test, measurement and diagnostic equipment (TMDE) calibration.

Processes for the modernization

Following initial outfitting, the Integrated Product Team (IPT) is responsible for CALSTDs, sustaining calibration processes for the modernization, logistical support and optimization required to support fielded weapon systems, R&D, test and evaluation and base operating support facilities, to name a few.

We have provided the NAVAIR METCAL with logistics, engineering and technical services for CALSTDs allowancing, inventory management, technical data management, metrology engineering, technical document development, calibration readiness modeling, process development, training and subject matter expertise.

We can help your organization establish its own calibration and production test environments or help you improve your existing capability.

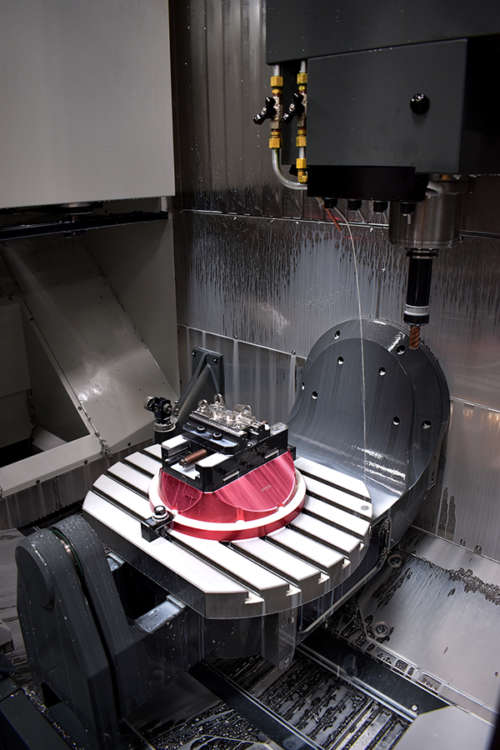

COMPLEX MANUFACTURING

WHEN OTHERS FAIL, WE SUCCEED

Our manufacturing capability uniquely blends our engineering and fabrication capabilities. Where other manufacturing companies are foiled by complex assemblies, incomplete drawings, or unavailable tooling we thrive in that environment. We are an AS9100D certified company with a proven track record in delivering hard-to-get parts and assemblies.

Our expert engineering staff designs parts and tools and performs structural analysis and detailed modeling capabilities when non-reoccurring engineering is needed. Working hand-in-hand with our manufacturing floor, we can prototype, fabricate first articles, and qualify a production run. On numerous occasions, we have succeeded when others could not deliver.

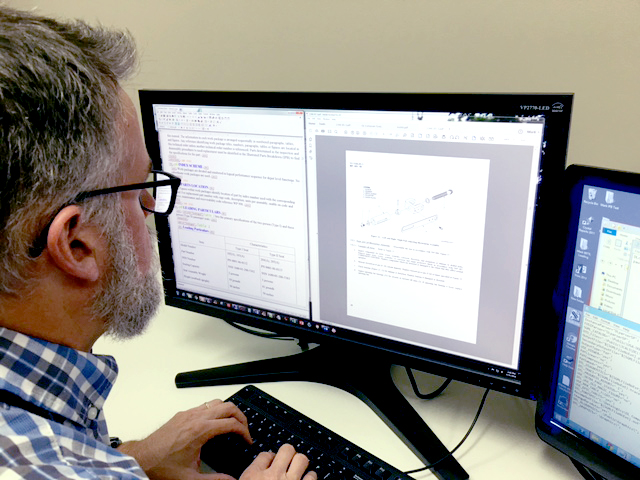

DATA DEVELOPMENT

TECHNICAL DATA DEVELOPMENT

Our technical data development for aircraft operation and maintenance is second to none. We employ a seasoned team of aircraft maintenance veterans who have been the end users of the products we develop and understand what it takes to deliver exceptional material. We have developed, validated and verified Technical Orders (T.Os) and Time Compliance Technical Orders (TCTOs) for organizational, intermediate and depot level activities.

We follow a rigorous process to ensure program source data information (typically engineering documents) provided is accurately captured and incorporated in all affected maintenance and operation T.O’s, TCTO’s and temporary modification directives (T1 and T2). We interpret a variety of engineering documents and translate them into easy to understand maintenance and operational language for the following types of T.O’s:

- Inspection

- Weight & Balance

- Flight Manuals

- List of Applicable Publications

- Munitions/Weapons Loading Procedures, Non- nuclear and Nuclear

- Weapon Delivery and Aircrew Procedures Manuals and Checklists

- Work Unit Code Manual

- Illustrated Parts Breakdown

- General System Manual

- Job Guide Manuals

- Fault Isolation Manual

- Wiring Data Manual

- Wiring Diagram Manual

- Aircraft Structural Integrity Program (ASIP)

- Overhaul Manuals

- JEDMICS-Compatible Level III Engineering Drawings

CONTINUOUS PROCESS OF DEVELOPMENT

We provide source data in necessary formats (Word, Excel, PDF, etc.) as defined by customer requirements; we also have the capability to develop and deliver complete manuals in Standard Generalized Mark-up Language (SGML).

KIHOMAC employs a cradle-to-grave, continuous process of development, review and validation to ensure every piece of engineering/source data information is incorporated in all the appropriate T.O’s, TCTO(s), T1 or T2; this process ensures we’ve captured the data in the clearest context possible.

We use a stringent configuration and data management plan to validate technical data being developed is from the most current and accurate baseline. We’ve established strict guidelines, a detailed folder structure that captures configuration and locks in baselines, and configuration audit requirements. These practices are vital to the T.O development process and ensure an accurate final configuration.

FIELD TECH SUPPORT

ENGINEERING AND TECHNICAL SERVICES

We have teams of seasoned aircraft maintenance technicians with vast amounts of field experience in our Engineering and Technical Services program. They have the capability to integrate into maintenance organizations and improve current capabilities by providing training on advanced aircraft systems, guidance on analysis of difficult maintenance issues and supporting sustainment engineering by improving the technical and quality deficiency reporting programs.

The capability exists to enable units to perform at much higher levels with a less experienced workforce when supported by CETS.

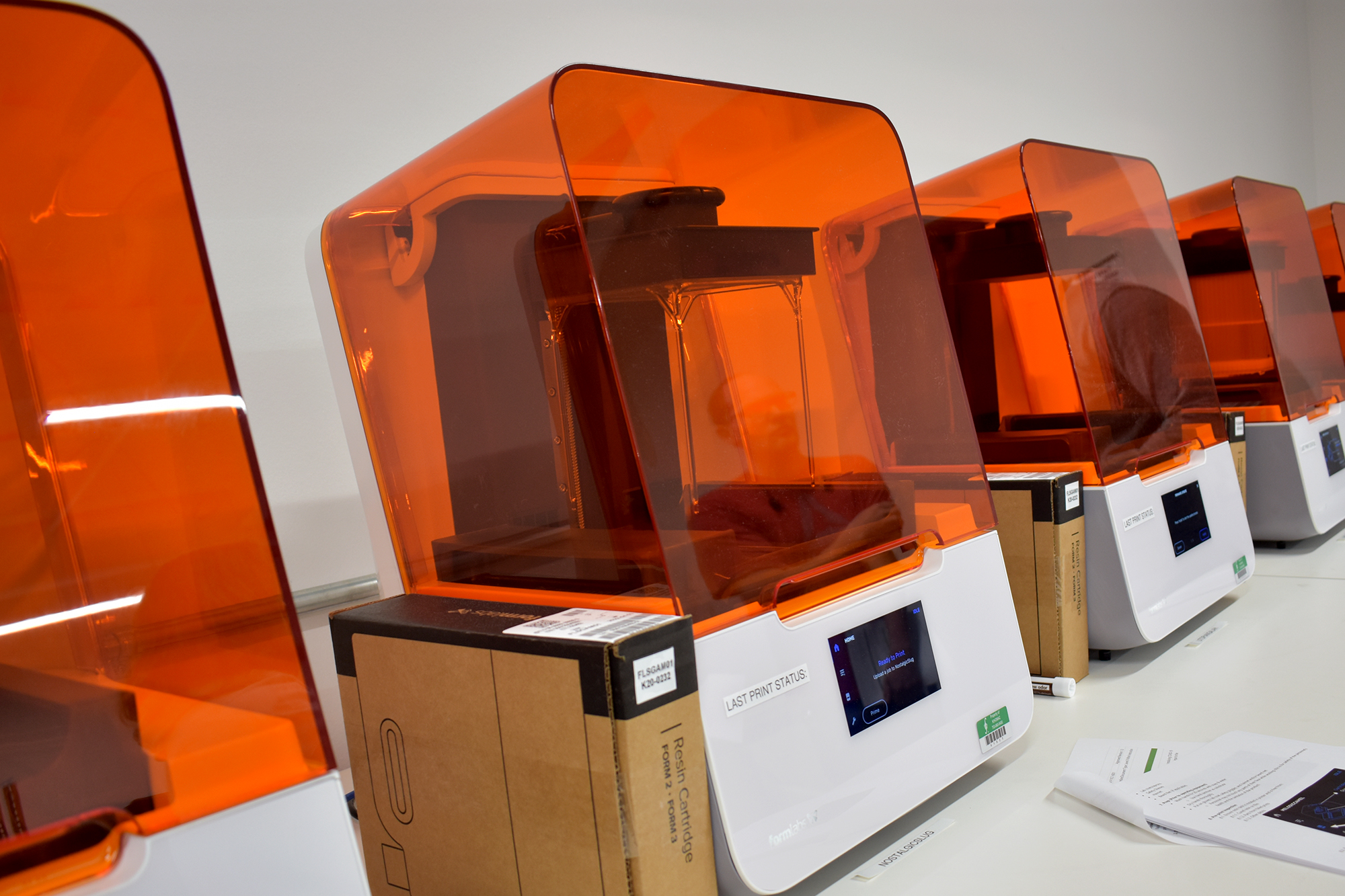

REVERSE ENGINEERING & PROTOTYPING

Building a Bridge to Future Platforms

As new aerospace platforms are introduced into the United States defense inventory, it is imperative that the current aerospace systems remain at optimum operational effectiveness during the transition. KIHOMAC’s proven reverse engineering and prototyping methodology on legacy systems has facilitated the life extension of several airframes, far beyond their original operational expectancy. KIHOMAC Engineering has an exceptional ability to garner the details from antiquated parts and technical data packages for re-production of long since discontinued parts & assemblies. KIHOMAC has reverse engineered 30 such assets over the last 9 years. Our streamlined prototype development process validates our assumptions, and prevents wasted production efforts. These successes have facilitated our number one goal, protection of America’s War Fighters.

Too Hard for Others, Just right for KIHOMAC

KIHOMAC specializes in the design and manufacturing of hard to procure parts and tooling. On more than one occasion KIHOMAC has successfully produced parts and or tooling when other contractors failed. Our dynamic approach to specialty manufacturing is the essential element enabling us to thrive in an arena where so many others fail, or refuse to try. Our design and development of tooling for parts fabrication has been integral in the configuration management, reproduction, and interchangeability of assets for aging aircraft sustainment.

SOFTWARE ENGINEERING

We take a systems approach to software engineering. We believe that a sound requirements baseline coupled with an agile development process is the key to success. Our software developers are dedicated to creating flexible solutions to key problems.

Whether that means a web application today or an on-aircraft mission system tomorrow, we find the right technology to suit the problem. Our team of dedicated developers supports a number of product lines, from the AT-6 Mission Planning System to the Combat Search and Rescue Gateway to FileRelay.it, an innovative solution to e-mailed file transfer. Whatever the challenge, we're prepared to meet it.

SUSTAINMENT

SUSTAINMENT

KIHOMAC has provided Life Cycle Sustainment Plan (LCSP) support across numerous platforms to include A‑10, AT-6, B-1, B-52, C-130, C-5, Cruise Missile, E-3, KC-135, F-16, ICBM, QF-4, and U‑2. Through our Predictive Analysis tool we provide a holistic systems approach for early identification of a fleet’s non-mission capable (MICAP) drivers, as well as the timely development of corrective actions to permit their rapid execution. Our goal is to ensure RIGHT PART, RIGHT PLACE, RIGHT TIME to meet warfighter needs.

We led the team supporting the A‑10’s field-level Consolidated Install Upgrade Program. Furthermore, we have established ourselves as a leader in technical data cleansing and Diminishing Manufacturing Sources and Material Shortages (DMSMS) parts obsolescence resolutions.

We provide Time Compliance Technical Order (TCTO) tracking; technical data development, validation and verification, and publication support. We have performed the refurbishment of legacy platform components, both mechanical and metals. Recently, we were selected to provide Engineering Services and Integration support to the U-2 Program Office.

We have developed and implemented Depot Pre‑Induction inspection plans, as well as maintained and updated engineering baseline data and wiring sustainment on various programs. Most recently we are excited to be providing both mechanical and electrical/electronic component production of a ground-based data cartridge reader used to decipher in-flight data from four types of data cartridges that collect data from F-16, F-16 FMS, F-16 EPAF, F-22, A-10, and B-52 platforms. The project involves all aspects of production management from parts acquisition, to prototype development, First Article acceptance testing, pre-production, Low Rate Production (LRP) and Full Rate Production (FRP).

SYSTEMS ENGINEERING

KIHOMAC views legacy systems as the major building blocks of military capability. In budget-constrained times, we need our systems to fly longer, be more versatile and maintain relevancy. As legacy weapon systems age, they need expert technical solutions to complex problems. We're committed to solving legacy system challenges in the here and now. KIHOMAC builds solutions from the ground up, mixing old-school systems engineering principles with 21st-century tools to develop the roadmap necessary to meet each platform's specific needs. Whether it's integrating new technology from the research labs, reverse engineering a critical component or architecting the next 30 years of aircraft upgrades, our people bring a unique blend of technical capability and passion for supporting the end customer.

We led the team supporting the A‑10’s field-level Consolidated Install Upgrade Program. In so doing, we have established ourselves as a leader in technical data cleansing and Diminishing Manufacturing Sources and Material Shortages.

MEASUREMENT SCIENCE

EXPERIENCE

We specialize in metrology and calibration solutions for the federal government, high technology manufacturing and test facilities.

The proper application of measurement science in these environments reduces cost while improving performance, reliability and product quality. We can help your organization establish its own calibration and production test environments or help you improve upon your existing capability.

QUALITY

Our services include engineering analysis, design and development of calibration systems, test systems and measurement assurance programs.

We have in-depth knowledge and expertise in delivering a wide range of measurement science programs including life-cycle management of precision measurement equipment, conformance with ISO/IEC 17025 and ANSI/NCSL Z540 standards, development of test procedures and calibration logistics support services.